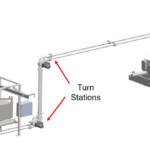

The Sure-Flo S210 Series Clean Bedding Delivery System is a tubular drag-chain conveying system designed to transport dry clean rodent bedding within a cage wash facility to an automatic bedding dispenser unit.

Key Features

- Solid Construction – Systems are available in either stainless steel, including the conveying chain, or in painted carbon steel with carbon steel chain. The system provides a maximum capacity of 2200lbs/hr [997kg/hr] of continuous conveying.

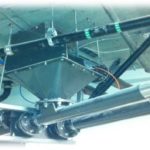

- Chain Link Assembly – The conveyor consists of a continuous true chain link mounted with solid circular disks which are a two-piece bolted design made of UHMW. The split disk design enables changing only the bottom half-disk which is subjected to wear.

- Continuous Tensioning Station [Patented] – A chain tensioning station takes up slack in the chain and automatically adjusts for tension changes. Proper chain tension minimizes wear, reduces downtime and maintenance costs, and the possibility of the chain being misaligned.

- Minimal Space Required – A typical Sure-Flo system consists of conveying piping, UHMW disks, chain, main drive station, continuous tensioning station, inlet port, bedding dump station, discharge port, and a control panel. No additional space is required for a mechanical room.

- Energy Savings – Each system consists of a main 3hp drive motor which pulls the chain. Optional 1/2hp turn station motors which assist in the horizontal or vertical change of direction may also be used. Typical system energy requirements are considerably less as compared to vacuum systems.

- Individual or Bulk Bags – A free standing clean bedding loading hopper is used for individual bags and our I-Beam Hoist and Frame system is used for large bulk bags. Multiple inlet ports can be utilized in one Sure-Flo system.