Life science facilities are required to adhere to numerous sanitation regulations to create a clean and safe environment for both animals and employees. One key aspect of these requirements includes cleaning animal caging by removing and replacing the bedding materials. Some animal research facilities are realizing just how advantageous utilizing chain drag systems can be for this process – but just how and why are they so beneficial?

The necessary process of soiled bedding removal and replacement of clean bedding is full of health hazards such as exposure to allergens. Further, there is the physical labor aspect which can put employees at risk of occupational injury. And finally, there is the time that it takes to complete the soiled bedding removal and clean bedding replacement process – which can be significant, especially in larger facilities.

Chain drag systems can be a solution that has helped numerous animal research facilities cut down on the process risk, time for completion, and even overall costs. So just how does a conveying system like this fit into vivarium research operations?

1. What is a Chain Drag System?

First, let’s clarify what chain drag systems are and how they operate. They are a continuous series of disks attached to a chain pulled through a transport pipe with electric motors to convey bedding and materials. These types of systems are quite commonly used in agriculture, mining, manufacturing plants, and other material handling applications.

Chain drag systems are just one of the types of bedding conveying solutions used in animal research facilities. Vacuum systems are also quite common, using air vacuum to transport bedding and materials.

There are numerous benefits to vacuum systems, as they are effective and sanitary. However, chain drag systems are far more energy-efficient and use fewer resources for operation. Further, vacuum systems are prone to clogging, especially when handling moist soiled bedding.

2. Conveying for Soiled Bedding Removal

As mentioned, numerous challenges come along with soiled bedding removal. There is the risk of sanitation hazards, physical health risks, and the time and resources required to complete the process.

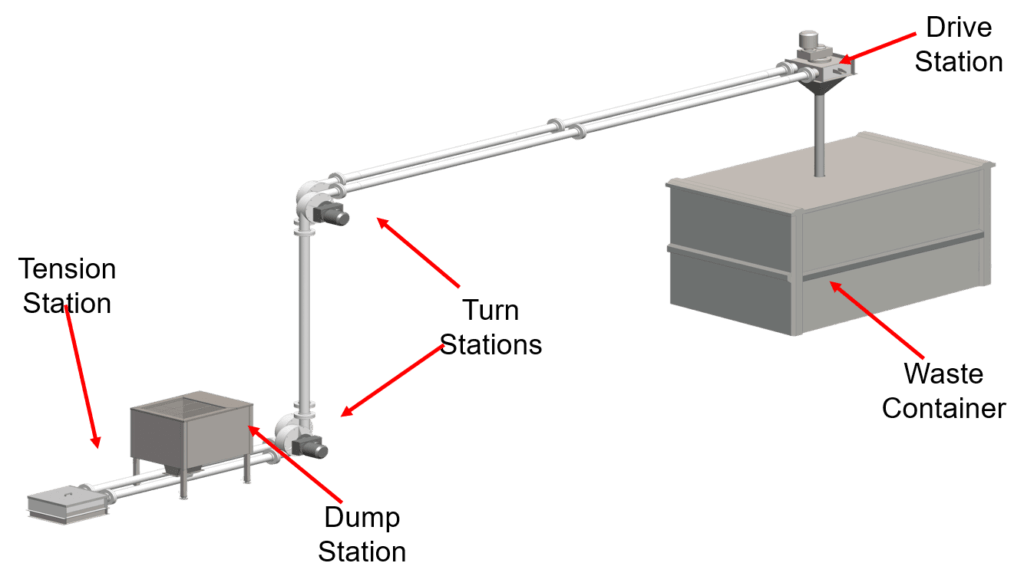

The S200 Sure-Flo Soiled Bedding Removal Solution uses a tubular chain drag system to efficiently capture soiled bedding and transport it to a disposal unit. The conveying system uses piping with flanges and clamps, so no dust or particles from the soiled bedding can escape as it is transported.

The chain drag systems main drive station, with assistance from turn stations and the tension station, pulls the chain with disks through the transport piping in a continuous loop from the dump station to a waste container.

This system uses a patented “continuous tensioning station” that automatically adjusts the chain to take up slack if the weight of the bedding changes. This helps to reduce wear and tear to the chain, improving system efficiency and minimizing maintenance costs.

3. Conveying for Clean Bedding Delivery Systems

Once the bedding has been fully removed and the cages are sanitized, new bedding needs to be placed inside. This process is considered easier than soiled bedding removal, but new bedding bags can be quite heavy. Further, dust may be released into the air as the bedding is dispensed.

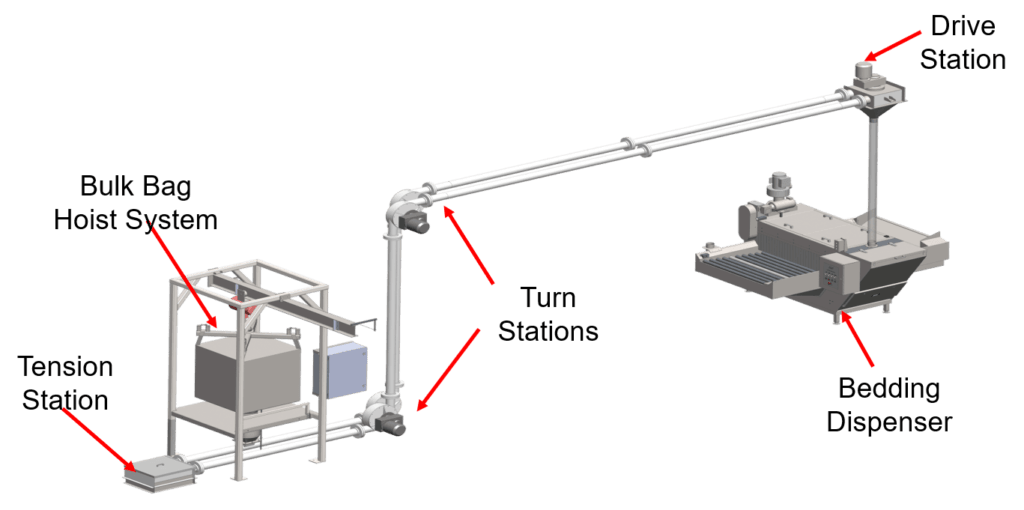

The S210 Sure-Flo Clean Bedding Delivery Solution uses a chain drag conveying system to quickly transport fresh bedding directly to a bedding dispenser where cages are filled.

This of course cuts down on turn-over time and also prevents accidental contamination during the bedding delivery process. This chain drag system operates similarly to the bedding disposal system, just with a bulk bag loader and bedding dispenser.

4. Conveying Drag-Chain Systems can be Integrated

Arguably one of the greatest benefits animal research facilities can experience from a chain drag system is the possibility of integration. BetterBuilt has uniquely designed the Sure-Flo solutions to be easily integrated into our automated life science systems, along with our cage washers and sterilization equipment.

This means that the entire process can be handled with minimal physical human labor. Businesses that have adopted automated solutions like a conveyor bedding removal system and delivery system have on average cut down operation costs by 25 to 40%.

Over to You

While the concept of chain drag systems is relatively simple, you can expect tremendous benefits when they are used for bedding removal and delivery. Further, when using the Sure-Flo solutions from BetterBuilt, you can easily integrate each part with other automated systems.

If you have any further questions regarding chain drag systems for use in your animal research facility, don’t hesitate to reach out to our team at BetterBuilt. Contact us to connect with a sales representative, technical support, or parts support for further assistance!