Decontamination and sterilization are essential for life science lab equipment. Germs, bacteria, and diseases can quickly spread if the tools used in the lab are not properly cleaned. Failure to properly clean equipment can also lead to cross-contamination with research materials, which could interfere with results.

For this reason, life science facilities invest in bio-decontamination. The market for both decontamination and sanitization equipment is projected to rise by 6% by 2024, hitting the $175 million mark in the United States.

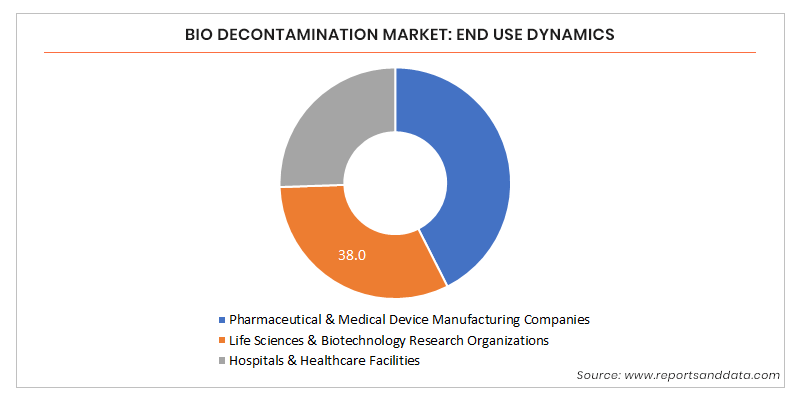

Further, the life science and biotech research industry make up nearly 40% of the bio-decontamination consumer market. They are exceeded only by pharmaceutical and medical manufacturing use.

Now, there is an important distinction to note between decontamination and sterilization. Although these terms are similar, there are some slight differences. Decontamination is the process of removing microbial contaminants from a subject or environment. Sterilization is a form of decontamination, but it also involves removing microorganisms, viruses, and bacteria.

The life science industry needs to use the proper lab sterilization and decontamination solutions. But there are various types of equipment designed for various purposes. So, which lab sterilization and decontamination tools are best?

Let’s discuss.

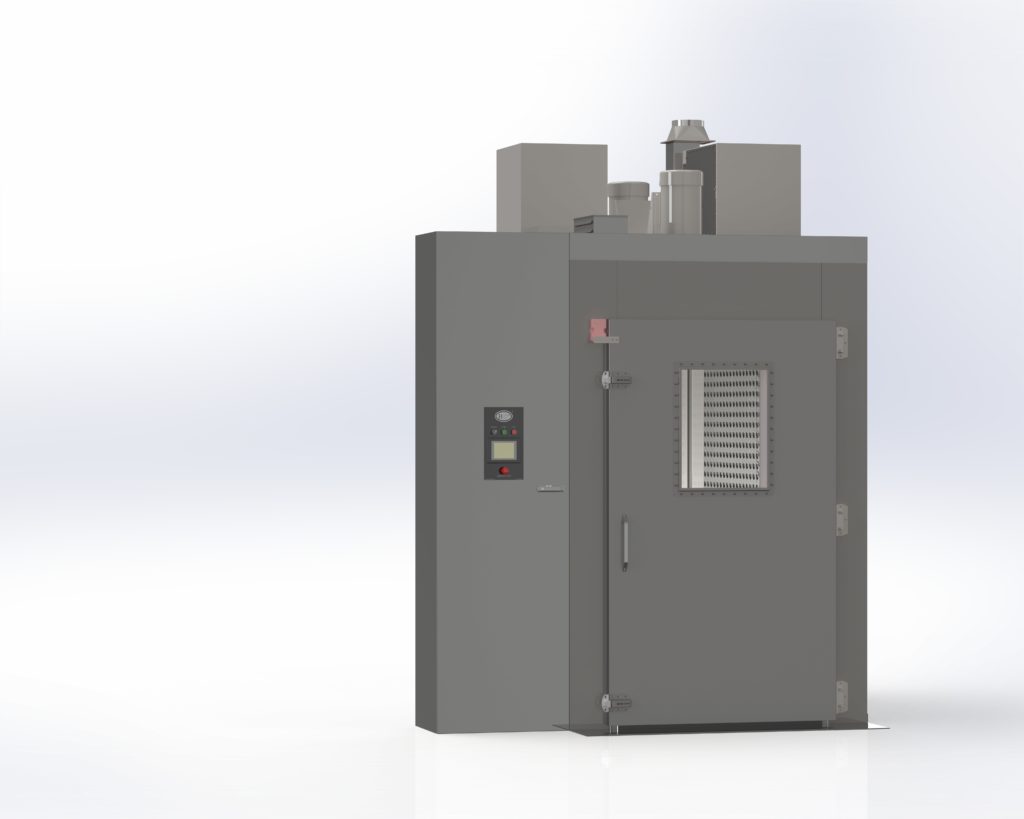

#1. Decontamination Chambers

Decontamination in life sciences requires controlled environments to effectively remove all microbial growth on the equipment. Additionally, washers or handwashing is not entirely effective for removing all growth in particular applications, such as biotechnology or the pharmaceutical industry.

Decontamination chambers are designed to create this disinfected, controlled environment. The equipment is then decontaminated with vaporized hydrogen peroxide (VHP) or chlorine dioxide (CD) that is distributed into the chamber.

The chamber must be tightly sealed during the decontamination process. Pneumatic gaskets on the chamber doors create an airtight seal once they are closed, which prevents any vapor or gas from escaping. The chamber can then be controlled via an exterior control system. Safety features are also installed to lock the doors or stop the process in case of an emergency.

Decontamination chambers come in a variety of sizes and are available with either single or double door entries. Larger units, such as the V700 Series, have chambers that can fit several loads of equipment at once.

Decontamination chambers are used to decontaminate equipment including:

- Material handling carts

- Various lab equipment and instruments

- Electronic equipment

#2. Dry Heat Sterilizers

Sterilization is a bit more thorough of a process that ensures that all microorganisms are destroyed. Some sterilization solutions use steam to thoroughly clean equipment. While this approach is certainly effective, it uses a lot of water and energy resources.

Dry heat sterilizers do not use steam, but instead, use electric-generated high temperatures to kill microorganisms.

Hot air is circulated through HEPA filters in both the intake and exhaust systems. This prevents any contaminants from entering the chamber and compromising the sterile environment.

There are two types of dry heat sterilizer designs:

The D600 Series has a double-walled stainless-steel chamber for mobile cart loading. Doors are tightly sealed during the sterilization process.

The D600C Series is a conveyorized dry heat sterilizer. This allows for numerous mobile carts to be continuously processed as they are conveyed through the sterilizer chamber. This continuous operation may be ideal for some life science industry facilities especially those with certain automation systems. Additionally, dry heat sterilizers are more efficient and have lower operational costs than steam sterilizers.

Dry heat sterilizers are ideal for processing caging used in the care and housing of laboratory research animals and other materials used in laboratories.

Which is Best?

Decontamination and sterilization equipment are both essential to keep life sciences laboratories operating. However, both of these solutions are best for specific applications.

Dry heat sterilizers can be used for:

- Glassware sterilization

- Animal research cages

Decontamination chambers are designed for:

- Material handling carts

- Water sensitive equipment such as electronic devices

- Tools and instruments

Overall, both decontamination and sterilization solutions are necessary for various purposes in the life science industry. Depending on the type of equipment used in your lab, one or both of these devices may be needed.

The Wrap

Ensuring a safe and clean life science laboratory starts with having the proper cleaning solutions for all pieces of equipment. Decontamination chambers and dry heat sterilizers are both highly effective at killing microorganisms commonly found in these facilities. Each is used for specific purposes – so one is not necessarily better than the other.

If you have any further questions regarding these types of solutions, please contact our team of experts at BetterBuilt. We provide washing, sterilization, and decontamination systems for life sciences and laboratory research facilities. Our team can answer any questions and help you determine which solution is best for your laboratory.